Automation Solution

━━━━━━

Engineering smarter, more automated factory systems

Visionwell is offering a comprehensive solution in designing and manufacturing all kinds of specialized machines and production lines according to customer requirements. As we handle the process from initial design to com- missioning and post-install line optimization, you'll have a single point of contact in the form of a project manager. This is your advocate within Visionwell who takes responsibility for ensuring your project is delivered on time and to specification.

- Automatic machine for product & Integrated automation solution

- AI Integrated Machine Vision

- Robotics & Packing Solution

- Design electrical cabinets

━━━━━━

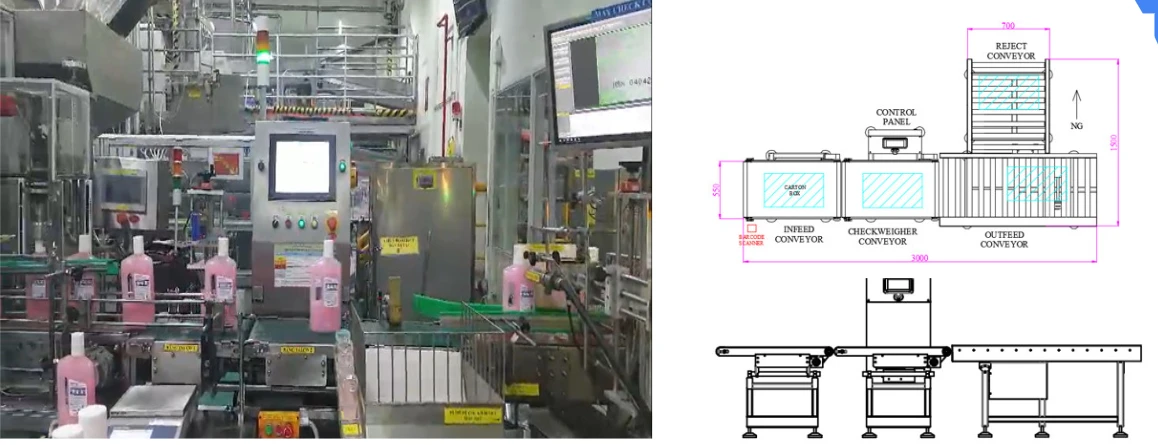

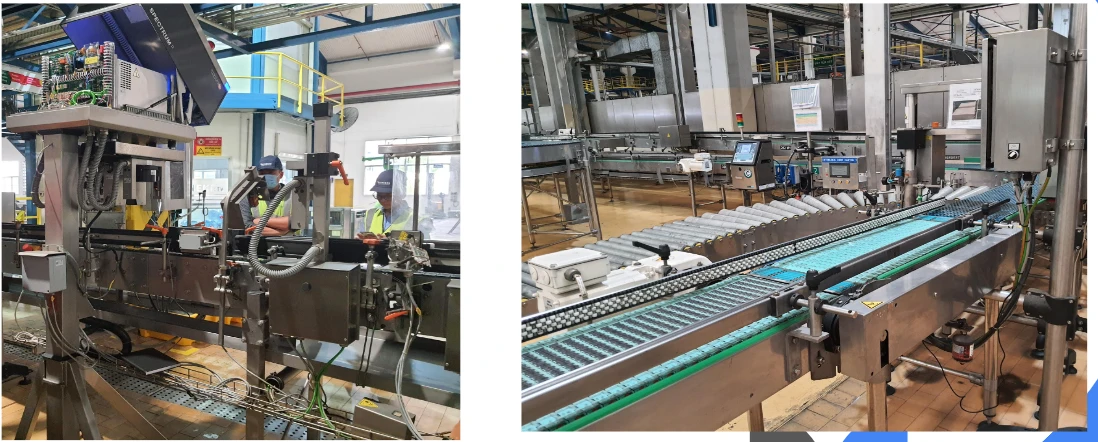

Automatic machine for product & Intergrated automation solution

The Visionwell engineers can provide support to your team for any automation project from simple retrofits to integrating automation throughout your process. We can upgrade your manufacturing with plant-wide automation. If your machine's electrical and automation control systems are failing you, a controls upgrade is a cost effective alternative to purchasing new equipment.

PLC CONTROLS - The Visionwell control engineers have extensive knowledge and experience in working with everything from PLC5 controls to innovative ControlLogix controllers.

MOTION CONTROLS- Visionwell understands how important it is to effectively and efficiently manage all moving parts in an industrial control environment. From single-axis servo drives for simple applications to multi-axis, high performance servo drives for advanced motion control, the Visionwell engineers can design, integrate, and support the best solution for your process.

Fixgure: Automation weigher

Fixgure: Automation weigher

━━━━━━

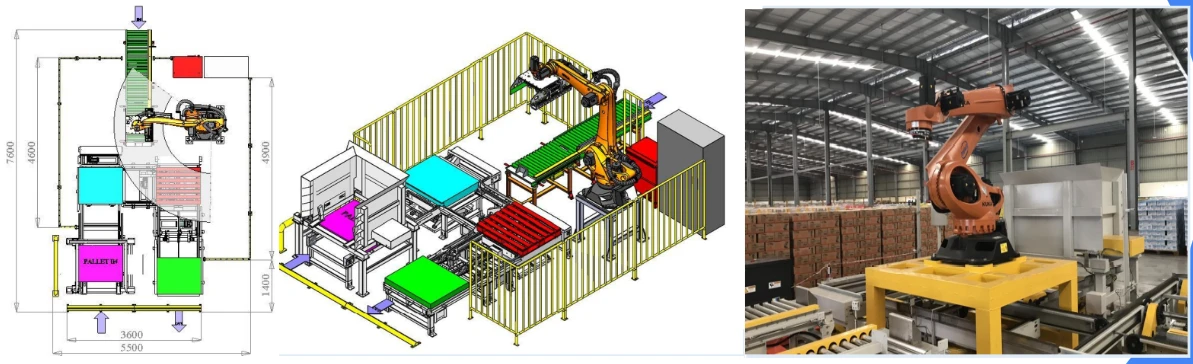

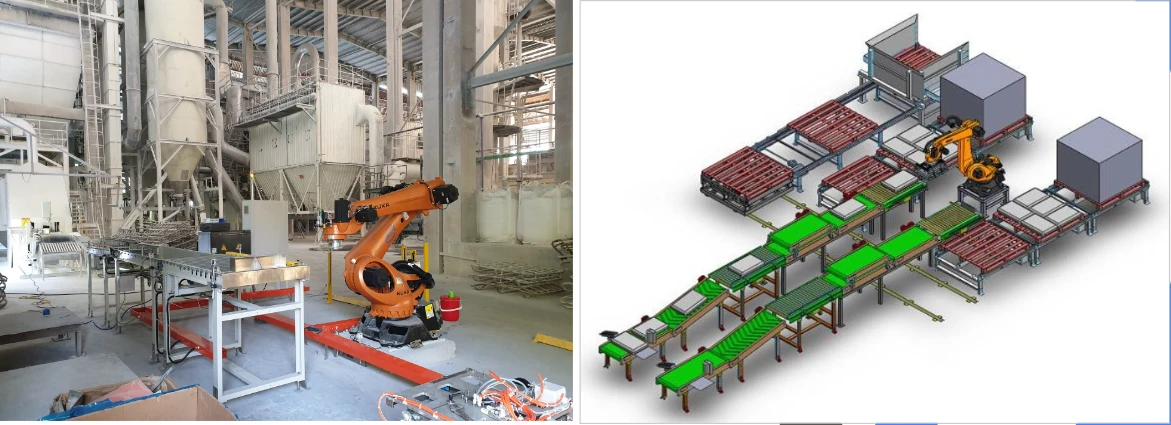

Robotics & Packing Solution

Custom robotics services & custom manufacturing robotics

At Visionwell, our staff of mechanical and electrical engineers thrive on creating custom solutions for your specific needs. We will explore and research your manufacturing process to build a specifically tailored automation solution for your process.

CONSULTATION - Visionwell can provide engineering expertise to consult on your upcoming project. Utilizing our years of experience in the custom machinery field will lead to the most efficient and cost-effective solution to automate your process.

DESIGN - The Visionwell engineering team works directly with our customers to learn your procedure, expectations, and specifications. Integrating those into the design phase means decreasing time to production.

END OF ARM TOOL - Our engineers can design a solution to meet your exact needs when you can not find a robot gripping tool off the shelf to perform your needed task. After evaluating your robotics platform, part handling conditions, tolerances, cycle time needs, and throughput requirements, the Visionwell team will design and build exactly what you need.

WORKCELL DESIGN - Safety is our top concern when designing machinery for your process. Our engineers collaborate with you to design the entire work cell from robot to safety guarding. From mechanical design, fabrication, and assembly you can trust that you will receive a technically proficient solution.

INTEGRATION - The Visionwell team will manage all aspects of your project. Once our design is finalized, we will build and install your new machine. To increase immediate productivity, Visionwell can provide on-site support to train your operators on proper usage of the new machinery. Well trained operators is the key to making the most of your new.

Picking robot & Palletizing system 1in-1out

Picking robot & Palletizing system 1in-1out

Picking robot & Palletizing system 2in-2out

━━━━━━

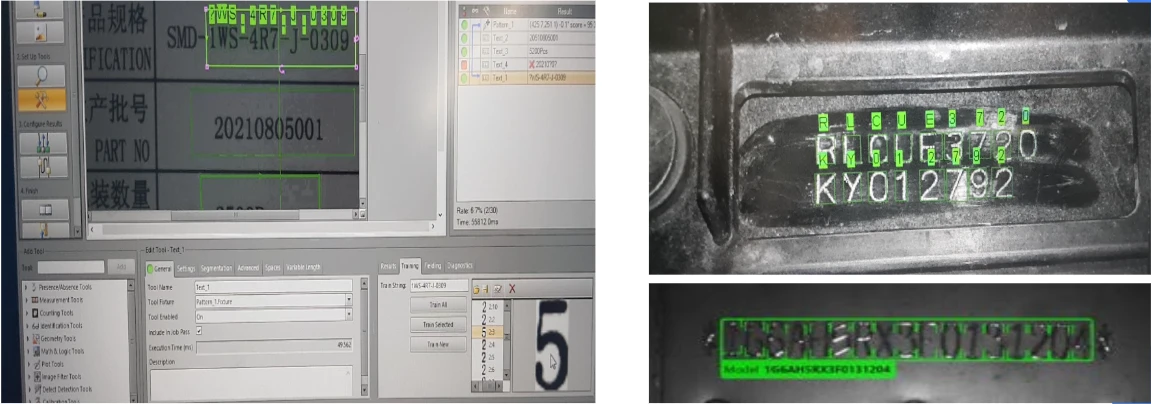

AI Integrated Machine Vision

Machine vision applications that can help you tackle your specific challenges while decreasing operator error and fatigue. We utilize best in class, off the shelf, industrial rated 2D and 3D vision products to tackle some of the toughest manufacturing problems.

SENSING TECHNOLOGIES - Technology is advancing and changing quickly. Let us keep your process operating a peak efficiency with the latest developments in sensing technologies, adaptive software, and smart safety technologies.

VISION INSPECTION SOLUTION - Implementing 2D and 3D cameras to drastically improve quality inspection, fault detection, and condition monitoring. Visonwell's goal is to provide you with solutions that will produce accurate and repeatable results, improving quality, and providing warning systems to minimize expensive product loss and downtime.

POROSITY INSPECTION - If your casted product needs to be pressure tight, you know just how problematic and expensive porosity defects can become if the less than quality part makes it through to production. Operator fatigue can mean missed defects. Visionwell has designed porosity inspection to ensure defects are detected and the operator is alerted.

Machine Vision – Deep learning recognizes deformed VIN code characters

Machine Vision – Deep learning recognizes deformed VIN code characters

Machine Vision with AI Camera verify caps are properly placed and sealed in F&B factory

━━━━━━

Design and assembly of electrical cabinets

CHEMICAL PROCESSING CONTROL CABINET / WASTEWATER TREATMENT CONTROL CABINET

info@visionwell.vn

info@visionwell.vn

-large.webp)